Woodworking Accessories Tips

Special PUR coating system for bevel sealing, how to achieve the ultimate in 45° bevel edge sealing?

Compared with the common “horizontal and vertical” panel furniture shapes, the designs of bevels, curved edges and other shapes are more eye-catching and can also meet people’s increasingly higher aesthetic needs. Moreover, with the current popularity of minimalist and light luxury styles, furniture design has also begun to become simple and complex. Various handle-free and other beveled edge special-shaped designs are emerging in an endless stream, and the quality is reflected in the details.

There are many factors that affect the effect of bevel edge sealing, especially the use of adhesives, which not only affects the texture of the board, but also has a great impact on the life of the board. Traditional bevel edge sealing mostly uses EVA. The edge sealing products of this adhesive are mainly aimed at popularization and sinking into the market. Therefore, if you want to target the high-end market, you must make high-quality bevel edge sealing, and the selection of adhesive is the key.

Special PUR coating system for bevel sealing, how to achieve the ultimate in 45° bevel edge sealing?

01 Bevel edge sealing and adhesive selection

The bevel of panel furniture is often seen in the design of handle-free cabinets and other furniture. The treatment of the bevel not only has the function of sliding the cabinet door, but also makes the furniture more simple and advanced. However, the bevel design of the board also brings about a problem, that is, bevel edge sealing.

There is another key point that cannot be ignored, that is the gluing process of edge sealing. If problems such as uneven glue application and glue overflow occur during the glue application process, the edge sealing effect will be seriously affected and the production cost will increase. Moreover, the performance of the adhesive directly affects the bonding effect of the edge banding. Therefore, the quality of glue application and the selection of adhesive play an extremely important role in the bevel edge banding process. However, for bevel seals that require higher quality, EVA hot melt adhesive is often difficult to achieve the ideal bonding effect. In this case, the emergence of PUR glue has significantly improved the situation.

02 PUR glue and PUR glue coating process

Whether it is EVA or PUR, the basic principle of edge sealing is the same, that is, hot melting. EVA glue is an ethylene acetate polymer hot melt glue, while PUR glue is a moisture-curing reactive polyurethane hot melt glue.

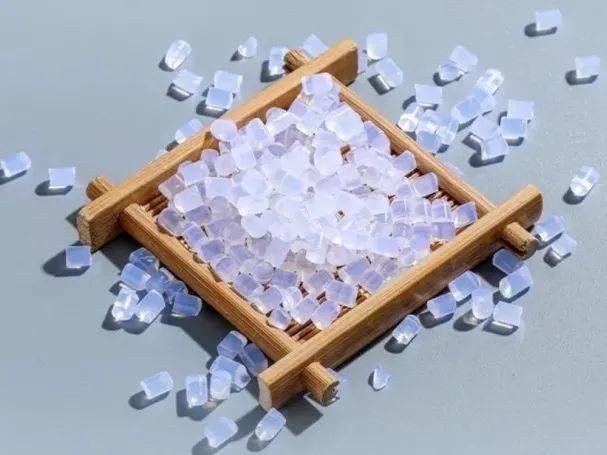

PUR glue is usually solid at room temperature. When used, it needs to be heated and melted into a liquid, and a high temperature must be maintained during transportation and glue application. The liquid PUR glue needs to be bonded to the edge strip immediately after being coated on the base material by the glue coating roller. The bonded PUR glue will produce a chemical cross-linking reaction with the base material and moisture in the environment.

Cross-linked and cured PUR has a higher adhesive strength than EVA glue, so you can obtain a good bonding effect with less glue than EVA. The amount of glue applied is less than twice that of EVA glue, and the glue line is tighter. Not obvious. And once the PUR glue reacts, it is irreversible, there will be no softening at high temperatures, and the furniture has a long service life. Therefore, the use of PUR glue can greatly improve the quality and aesthetics of the bevel edge sealing of the board. For furniture manufacturing companies that pursue high quality and high performance, using PUR for bevel edge sealing is a necessary choice.

In addition, since PUR glue will react with water, when applying PUR, it is necessary to consider the specific atmospheric environment of the PUR glue in the closed and sealed molten state to avoid side effects and solidification of PUR in contact with air. And in order to better control the curing reaction process of PUR glue, there are high requirements for precise temperature control of the pressure plate, hose and rollers. Therefore, in order to obtain excellent PUR edge sealing effect, a dedicated PUR glue coating system is required.

03 Advantages of PUR bevel edge banding

Since the amount used in the beveling process is less than that of conventional edge sealing, if EVA glue is used as the adhesive, the traditional EVA glue that has been exposed to high temperatures for a long time is prone to carbonization and discoloration at high temperatures. When used again, there will be obvious white edge sealing glue lines on the panels. Problem, the quality of the panels is greatly reduced.

The temperature of PUR glue is low, and the PUR special glue coating system adopts direct glue supply, which can significantly reduce the visibility of the glue line. The cured PUR glue has higher bonding strength and good stability, further ensuring the reliability of edge sealing quality. .

04 Conclusion

The quality of the furniture can be seen from the edge sealing details of customized furniture panels. Bevel edge sealing is a process that requires high equipment and materials in the manufacturing process of panel furniture. PUR adhesive has high bonding strength and excellent details, which can provide guarantee for bevel edge sealing and special-shaped curved surface edge sealing. It has gradually replaced traditional EVA hot melt adhesive in the market. Especially for furniture manufacturing companies that pursue high quality and high performance, using PUR glue for bevel edge sealing is an excellent solution.