Woodworking Accessories Tips, Woodworking Machine Tips

The Ultimate Edge Banding Machine Maintenance Guide: Secrets to Boost HOMAG Equipment Lifespan by 50%!

Complete machine

1. Clean the machine weekly. Only dry compressed air and a dry cloth are allowed to clean the machine.

2. Lubricate the upper pressure device (oil product number: 4-017-02-0035) and the height adjustment rail every month (run twice in the height direction)

3. Check the conveyor belt drive gearbox motor for overheating, abnormal noise and other faults every season. Replace the oil in the gearbox with new oil every 3 years.

4. Replace damaged conveyor chain blocks.

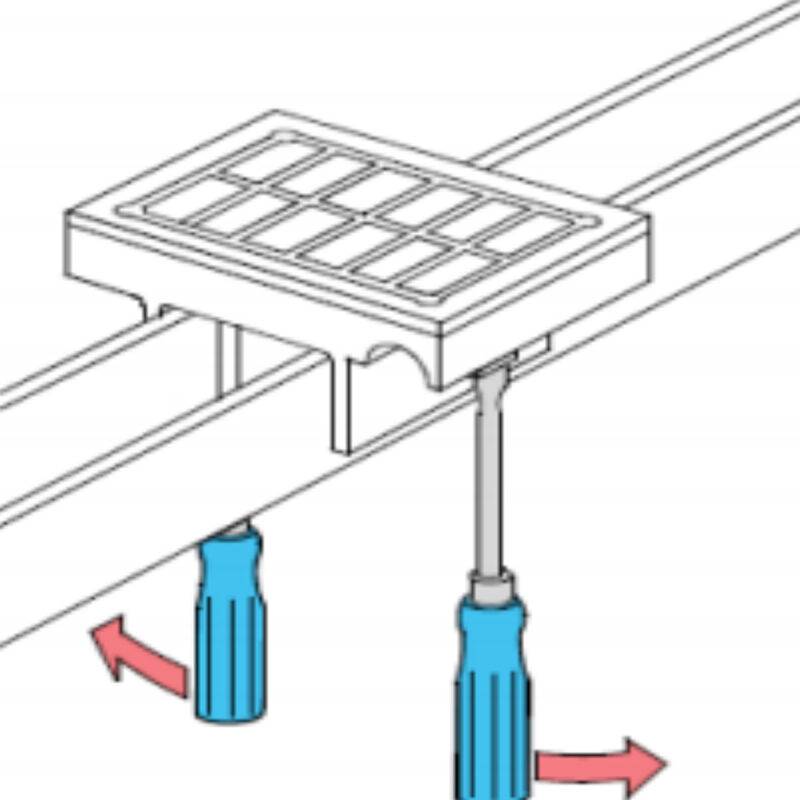

Note: When replacing a new conveyor block, you should first soak the new conveyor block in hot water at about 60°C and then press it onto the conveyor chain!

5. Check and adjust the tension of the conveyor chain every six months to prevent the conveyor block from tilting.

6. Lubricate the conveyor chain block and chain with engine oil every week

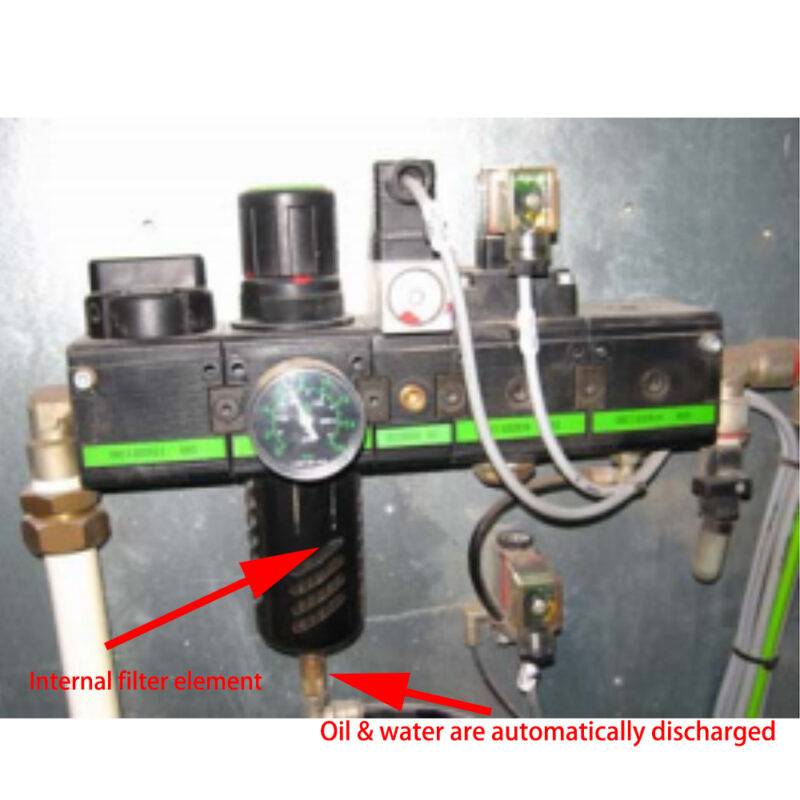

7. Clean the filter element of the compressed air filter every season. The oil and water filtered out at ordinary times are automatically discharged.

8. Check the function of the gas spring support rod and the protection switch on the machine guard flap every six months.

Computer part:

Take out the filter and clean it every 2 weeks to ensure normal heat dissipation and ventilation. Use a vacuum cleaner to clean the computer control cabinet every 6 months.

• Do not turn on the control power during the computer startup process!

• Do not turn off the power suddenly when the computer is uploading and downloading parameters!

• The computer must be shut down according to normal procedures!

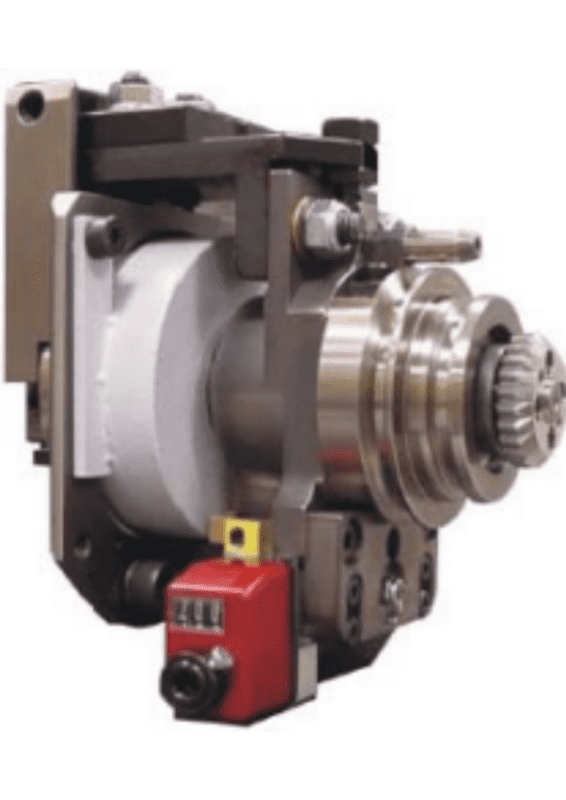

Gluing system

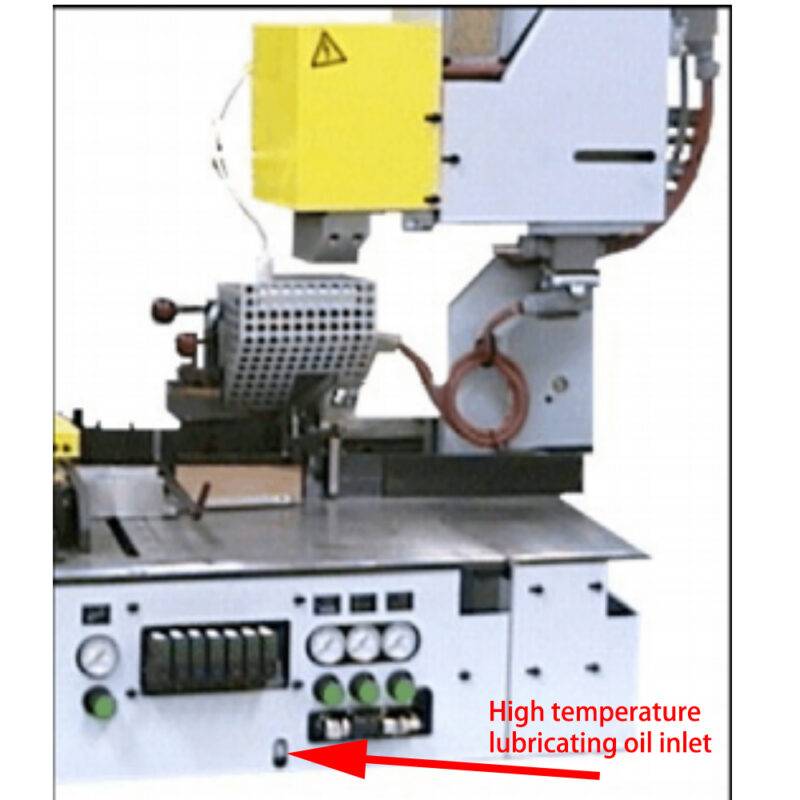

1. Lubricate the glue roller bearings every two days with high-temperature oil (HOMAG part number 4-017-02-0010)

2. Clean the glue unit monthly (do not use sharp-edged tools for cleaning).

3. Clean the drive joint shaft every 6 weeks.

Belt feeding device

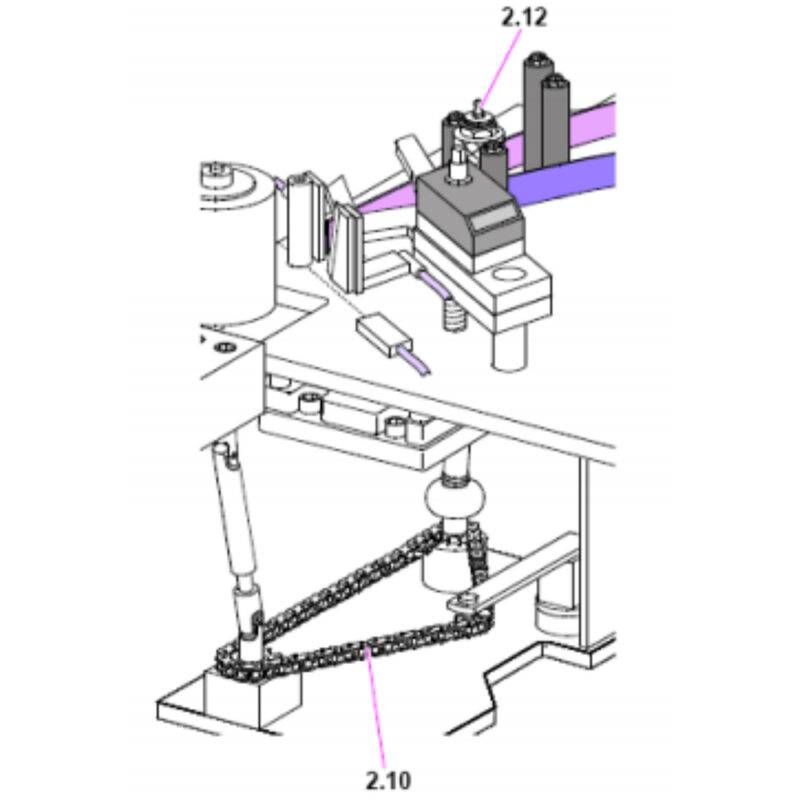

1. Clean and lubricate the conveyor chain every month. Use HOMAG heat-resistant bearing grease (HOMAG part number 4-017-02-0010) to lubricate the transmission chain (2.10 in the figure); lubricate the belt feeding wheel from the lubrication nozzle 2.12 (lubricant HOMAG part number is 4-017-02-3009).

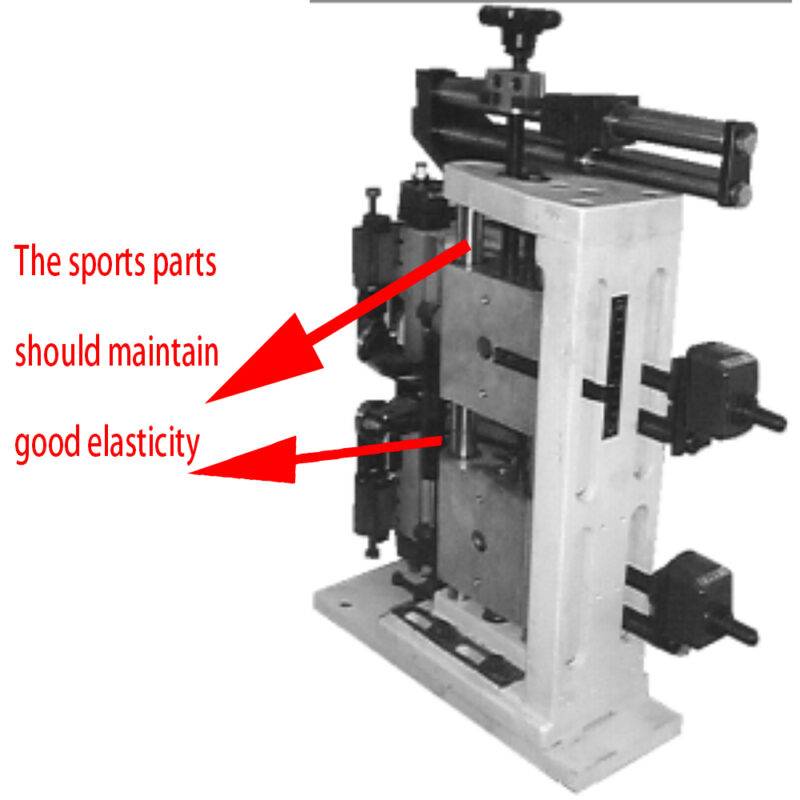

Front and rear trimming

1. Quarterly Linear guide Visually check the guide rail on the groove and move it back and forth to check for wear.

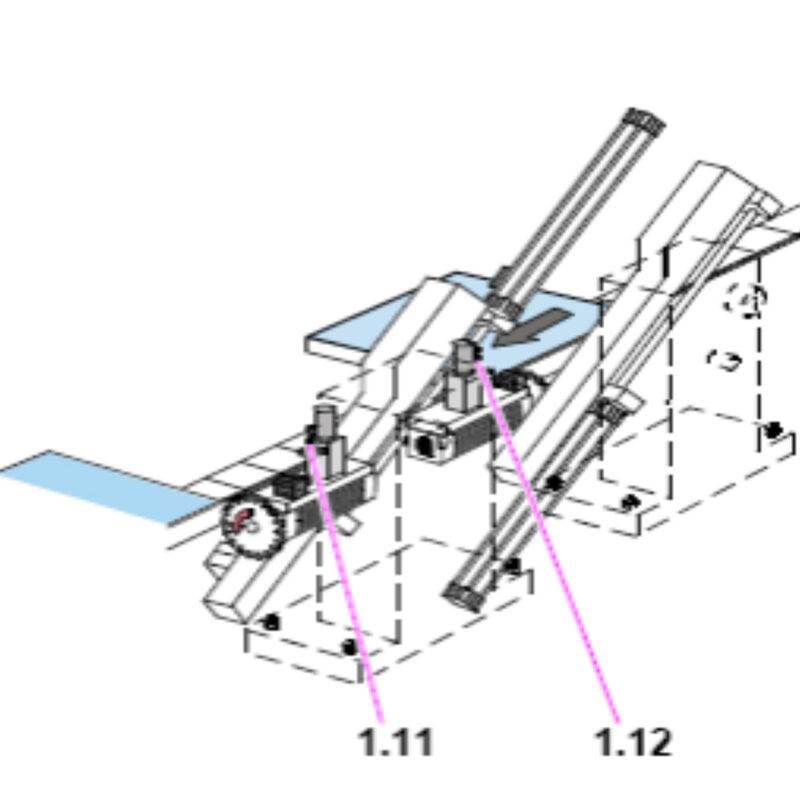

2. Monthly Buffers Manually check the resistance and flexibility of the downward buffer of the front trimming (1.10 in the figure) and the upward buffer of the front and rear trimming (1.11 and 1.12 in the figure).

Every 2 weeks Grease the guide rail slides, (lubricant HOMAG part number is 4-017-02-3009).

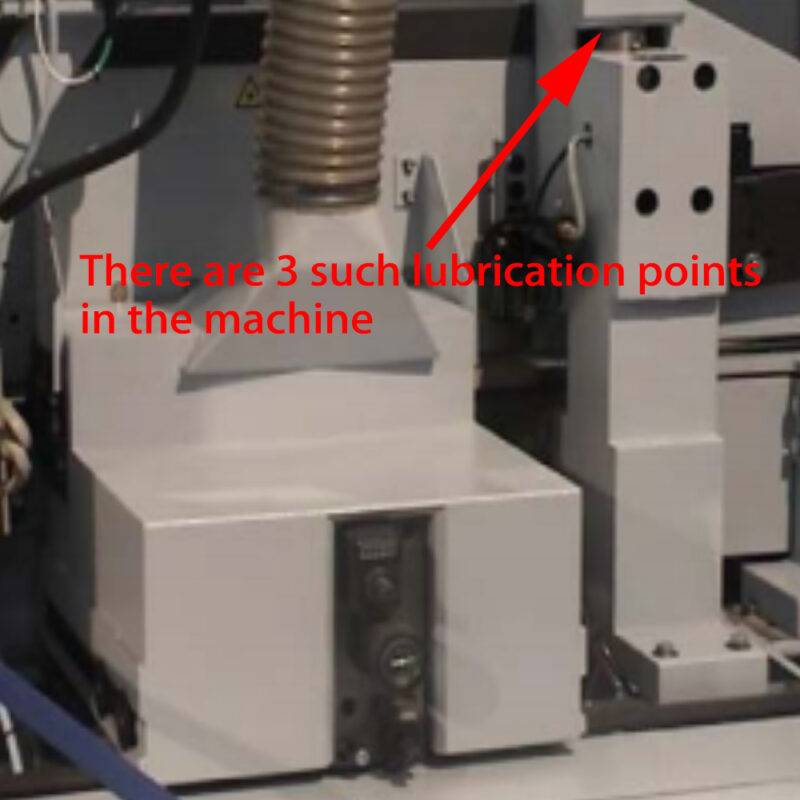

3. Visually check whether all guide rails are automatically lubricated.

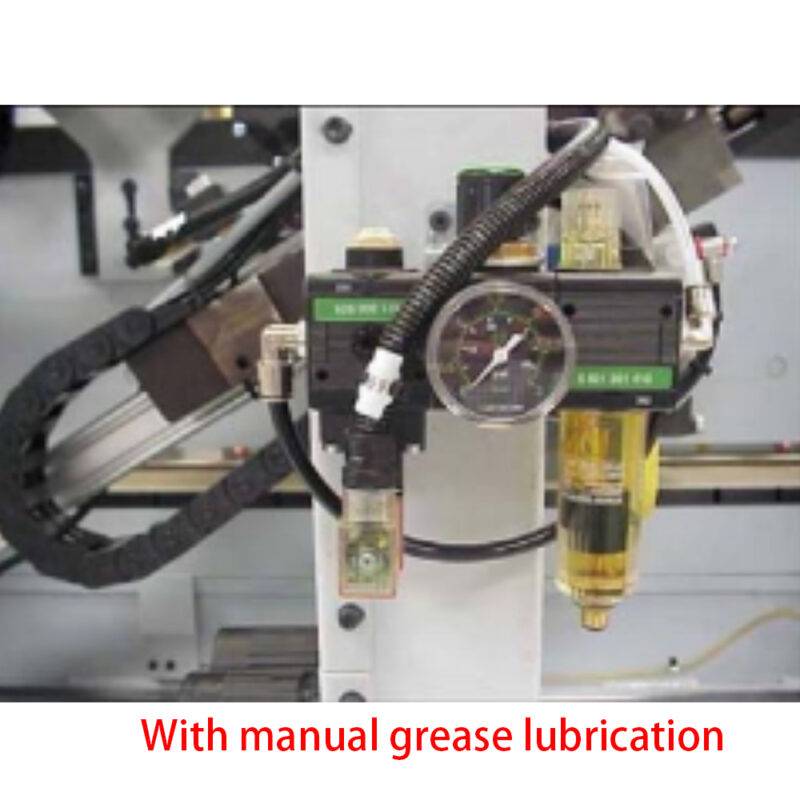

Automatic oil mist lubrication

Check and adjust the oil-air lubrication unit of the guide rail slide every week, add oil and adjust the amount of atomized oil (engine oil ISO VG 32 oil product number: 4-017-01-1035).

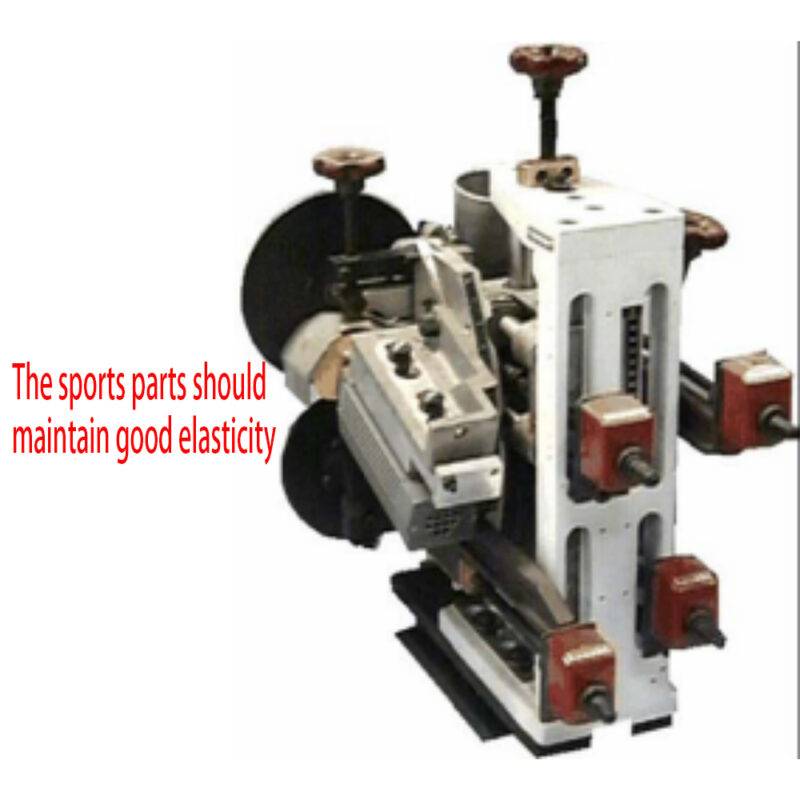

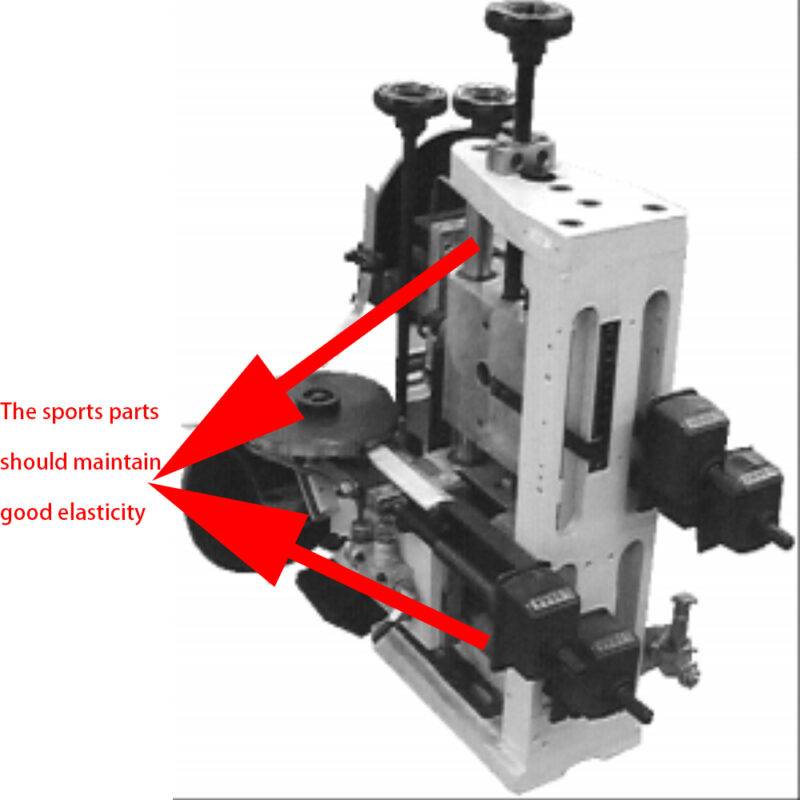

Upper and lower rough/fine trimming

1. Clean and lubricate (users provide their own ordinary engine oil) floating guide rods etc./moving parts every month

System tool

1. Check the exhaust hood weekly

2. Clean the exhaust hood weekly

Quick-change tool head

1. Check the tool for damage and the digital display for accuracy every six months.

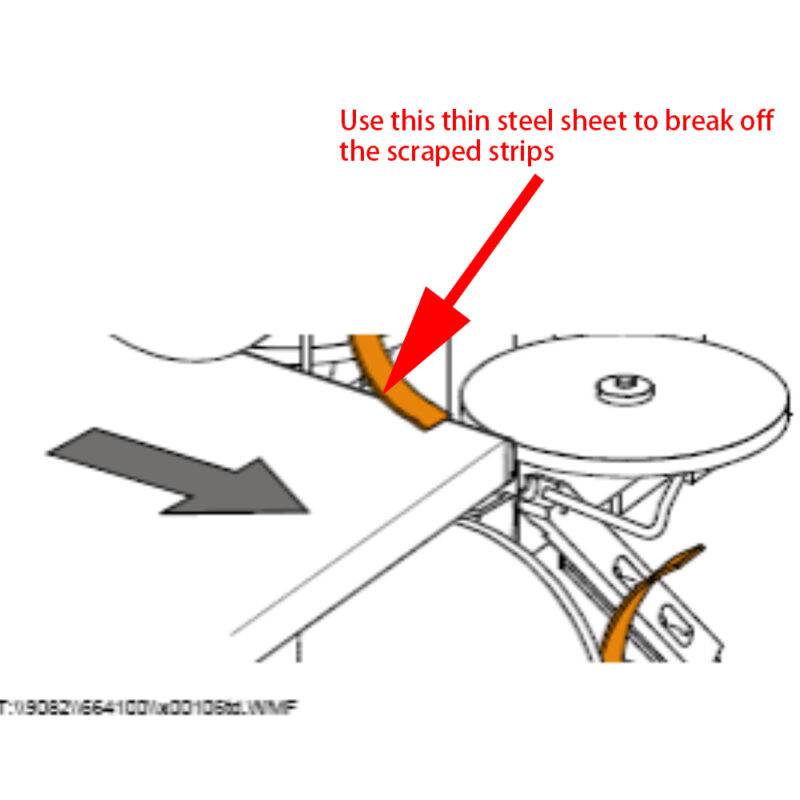

Scraper trimming

1. Maintain the chip breaker every season.

2. Clean and lubricate (users should prepare ordinary engine oil) floating guide rods and other moving parts every week to ensure that the horizontal and vertical wheels are always close to the workpiece; avoid scraped strips getting stuck between the wheels and the workpiece and affecting the edge sealing effect (mainly the dust suction wind force and whether the blowing angle is adjusted properly).

Glue scraping device

1. Check the tool for wear or damage every season.

2. Clean the spindle/moving parts and apply lubricating oil every month (users should prepare ordinary engine oil).

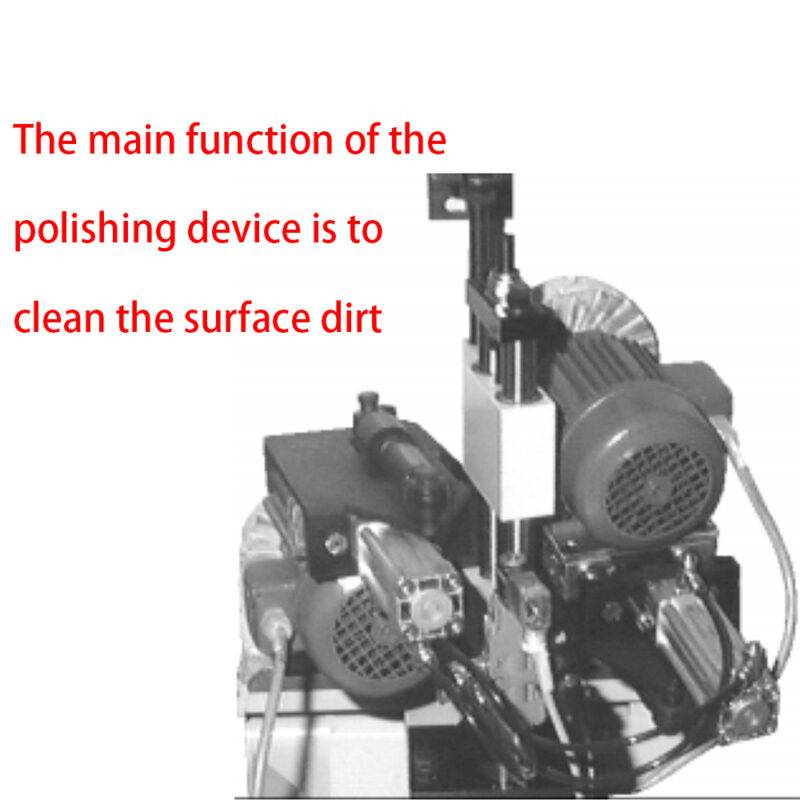

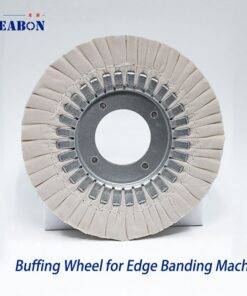

Polishing device

1. Clean and adjust the spindle every season, and adjust or replace the worn polishing cloth.