Woodworking Accessories Tips

Want good edge sealing quality, pay attention to the selection of adhesives.

In the field of decoration, finding a piece of furniture that meets your needs is often a difficult task. This requires not only high-quality raw materials, but also rigorous and mature processes. In panel edge banding, the role of adhesive is crucial. Since the edges of the boards are usually rough, they need to be sealed with adhesive to increase the beauty and durability of the furniture. In addition, the adhesive can also improve the waterproof performance of the board and prevent moisture penetration, thereby protecting the furniture from moisture and mildew damage.

When selecting an adhesive, its performance characteristics need to be considered to ensure it is suitable for the specific panel and edge banding needs. Today we will talk to you about the application of adhesives in board edge sealing.

01 Hot melt adhesive edge sealing

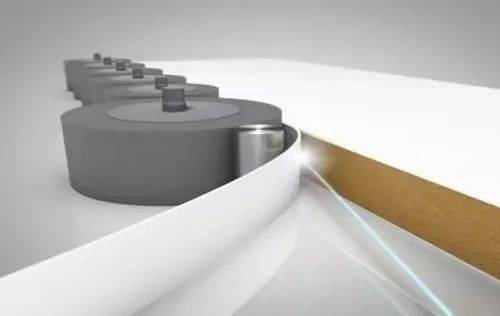

This glue is in granular form and needs to be heated by a special machine to melt the solid particles into a liquid form. Then, it is applied to the board and edge banding strip through the conveyor belt of the edge banding machine, and finally the edge banding process is completed by extrusion. This sizing process is the most traditional, technically mature and low-cost edge banding process.

Board edge banding is to bond the edge banding material to the edge of the board through an edge banding machine to achieve decoration and protection. Currently, hot melt adhesive is one of the mainstream edge sealing methods on the market. The specific method of use is to use professional sol equipment to melt the hot melt adhesive and apply it evenly on the board, so that the edge sealing material and the hot melt adhesive react physically or chemically, thereby achieving the combination of the board and the edge banding.

02 PUR glue

PUR, the full name of moisture-curing reactive polyurethane hot melt adhesive in Chinese, is one of the glues and is famous for its unique properties and uses. As can be seen from its name, it is different from traditional solid glue. PUR liquid glue has significant advantages in application methods. The dedicated liquid glue applicator uses even spraying to apply PUR liquid glue on the edge strips and cutting board cuts, making the application more even and using less glue. This method of even application not only improves work efficiency, but also results in better gluing results and stronger adhesion.

The advantage of PUR liquid glue lies not only in its uniform application properties. Since less PUR liquid glue is used, there is less waste and lower costs. In addition, PUR liquid glue also has the characteristics of rapid curing, which can greatly shorten processing time and improve production efficiency. At the same time, PUR liquid glue also has high bonding strength and water resistance, which can ensure the durability and stability of the bonding effect.

03 Laser edge banding

Due to the different forms of glue, the methods of applying glue are also different. The laser edge banding machine melts the glue on the edge banding strip through laser heating, and then presses it against the incision of the board to complete the entire edge banding process. The special edge banding strip used in laser edge banding has a smaller amount of glue. Compared with hot melt adhesive and PUR, the glue line is thinner and the effect is better. As for the effects of PUR edge sealing and laser edge sealing, according to statistics, 99% of industry insiders cannot tell the difference with the naked eye.

Currently on the market, in addition to using PUR hot melt adhesive for edge sealing, another major edge sealing method is laser edge sealing. However, there are big differences between the two in terms of cost and performance. First of all, the price of laser edge-sealed boards is much higher than that of boards edge-sealed with EVA and PUR hot melt adhesive. Secondly, the depreciation and maintenance of laser edge banding equipment require higher costs. Therefore, for most furniture manufacturers, hot melt adhesive edge sealing is a more economical choice.

04 Summary

In short, the application of adhesives in board edge sealing plays an important role in improving the quality and aesthetics of furniture. When selecting and using adhesives, specific furniture needs and material characteristics need to be considered to ensure the best edge sealing effect.