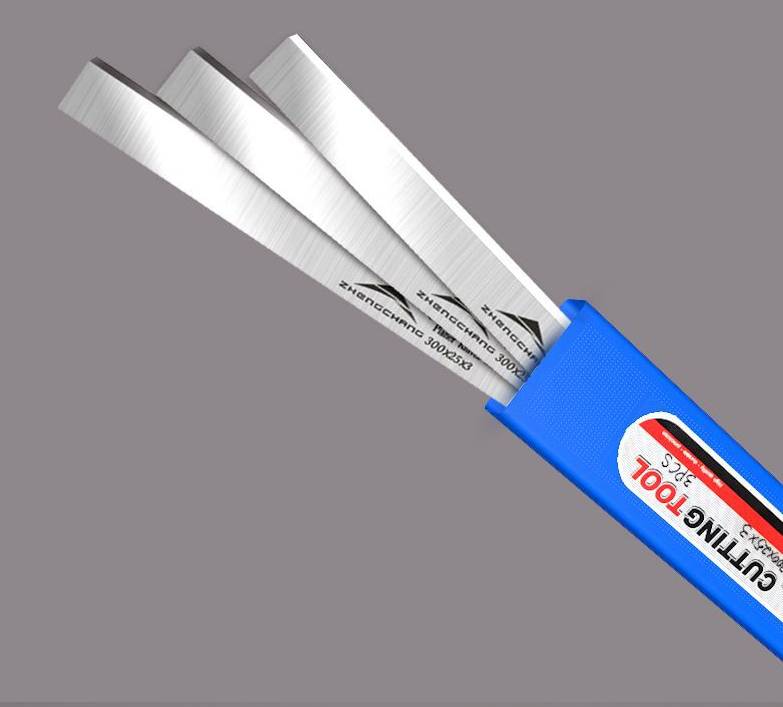

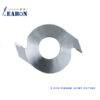

Woodworking W4% Planer Blade

$20.00 – $95.00Price range: $20.00 through $95.00

Specification

-

Product Name Woodworking HSS W4% Planer Blade Brand Name ZHENGCHANG / YH Model No. Type Single edge Color Silver Tone Dimension/mm(L*W*T) 80X25X3, 80X30X3, 90X25X3, 90X30X3, 100X25X3, 100X30X3, 120X25X3, 120X30X3, 150X25X3, 200X25X3, 200X30X3, 210X25X3, 210X30X3, 260X25X3, 260X30X3, 300X25X3, 300X30X3, 310X25X3, 310X30X3, 400X25X3, 400X30X3, 410X25X3, 410X30X3, 500X30X3, 510X30X3, 600X30X3, 610X30X3, 630X30X3, 640X30X3 Material HSS Package 3 Planer Blades per package

You might also need other models

W18% Planer Blade: Tungsten content is 18%, hardness is HRC63-64, notch is <0.4mm, good for cutting medium and soft wood such as fir wood etc.

W18% planer Blade

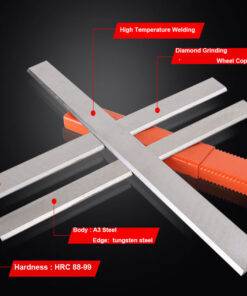

Click to learn moreTCT Inlay Alloy Planer Blade: Using Germany hard annoy, hardness reaches HRC90, notch is <0.1mm, superior material and complete new processing craftsmanship make product performance far exceed similar products. Super long life, good for cutting hardest wood and minimal grinding times are needed.

TCT ALLoy planer Blade

Click to learn moreFeatures

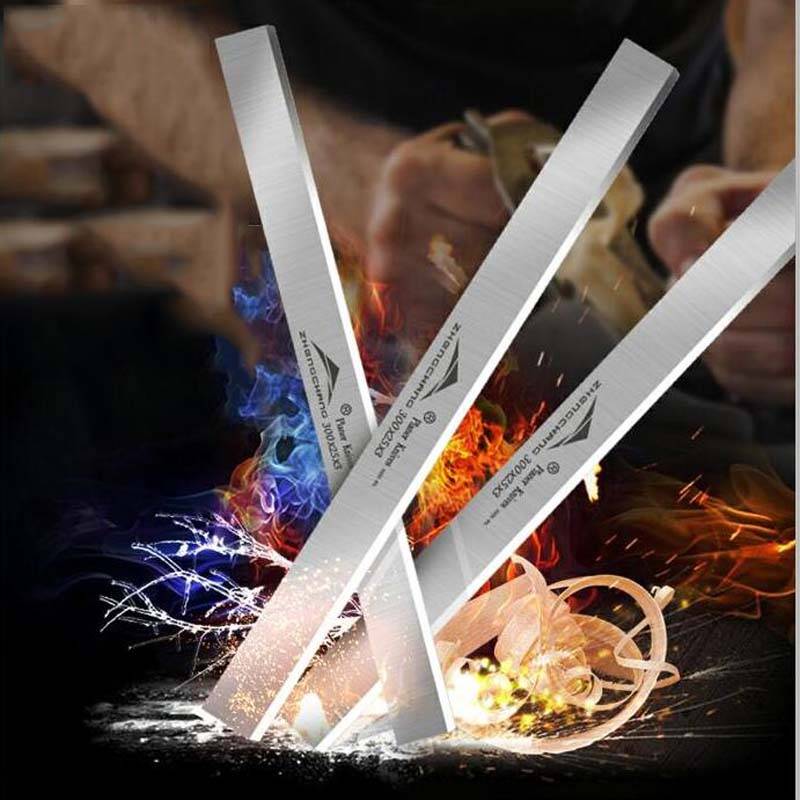

Preferred Material

Use high quality high speed steel. Cancining in salt bath furnace, easy to grinding, wear-proof, and the blade body is not easy to break.

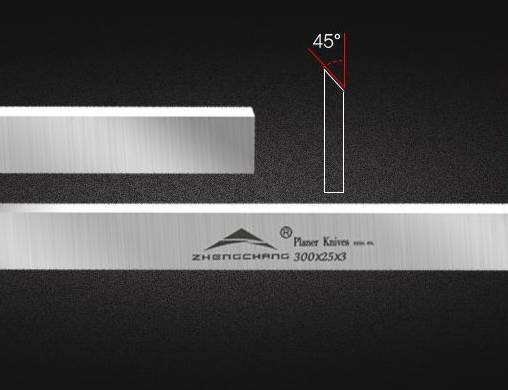

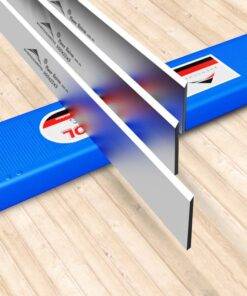

Opened Cutter Edge

Cutter edge was opened by advanced machine. It can be directly installed and used. Knife edge with good straightness and finish, so the cutter more durable and sharp.

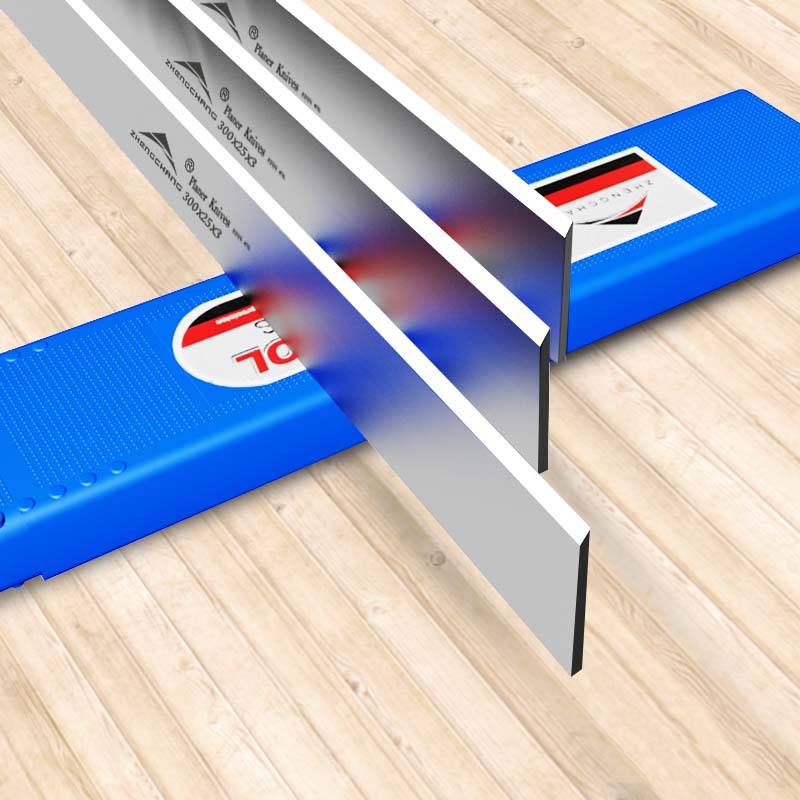

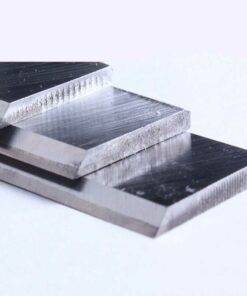

Strict Tolerance Control

The size tolerances of the blades are strictly controlled. Ensure that each blade size is within tolerance range.

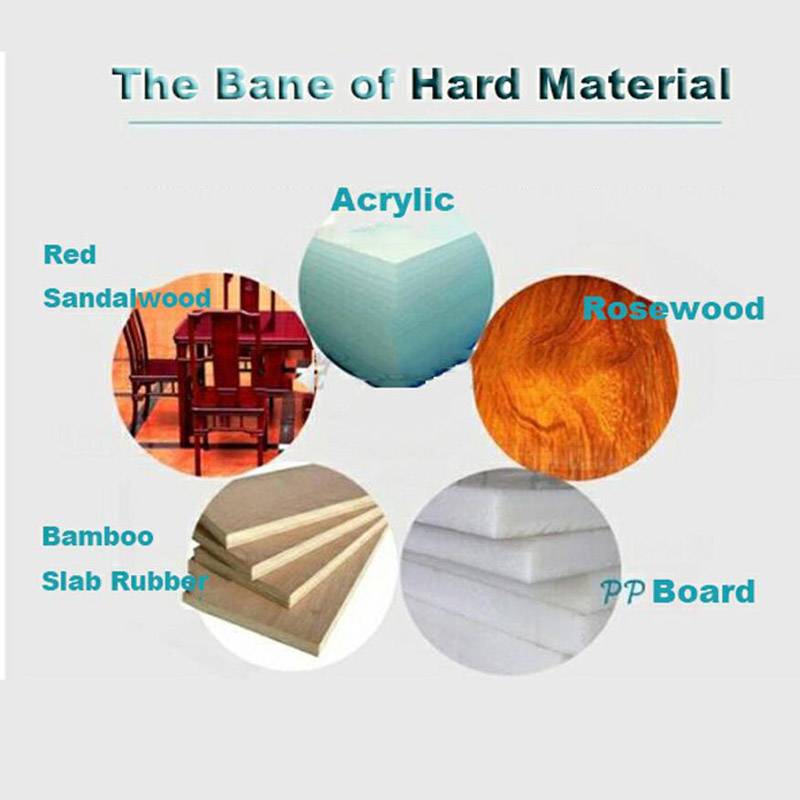

Applicable equipment and Material

Planer blade have sharp cutting edge, durable, it’s applicable for various woodworking equipment, can process both bamboo and wood products. Superior performance and long life, it’s a very cost-effective product.

Applicable Material: ordinary hard and soft wood, bamboo etc.

Applicable Machines: Single spindle milling machine, Router, Wood line machine, Surface planer, Thicknesser, Double planer, Four side planer etc. woodworking machines.

Processing Range: Furniture, Wood line, Photo frame, Crafts, Toys, Decoration Line, Wood flooring, Door, Windows etc. bamboo and wood products.

Woodworking Planer Blade Cutter Using Attention Points

1.Don’t use on cement, stones or metal .

2.Slow feeding speed should be better than faster.

3.Prevent the sawdust in wood from popping and hurting people.

4.Keep the blade straight by sharpening it often.

5.When put the cutter on machine, keep three blades in one circle.

6.All the screws which are used to press the should be fixed cutter should be fixed.

7.Use low planing speed , increase feeding rate and cutting edge depth.

8.Use reasonable cutter materials.

9.With good cutting angle, front angle, auxiliary back angle, cutter will be wear faster when the cutting edge angle is bigger.

10.Repair cutter point.

| Weight | N/A |

|---|---|

| Dimensions | N/A |

| Brand Name | ZHENGCHANG |

| Size(mm) | 80X25X3, 80X30X3, 90X25X3, 90X30X3, 100X25X3, 100X30X3, 120X25X3, 120X30X3, 200X30X3, 250X30X3, 260X25X3, 260X30X3, 300X25X3, 300X30X3, 310X25X3, 310X30X3, 400X25X3, 400X30X3, 410X30X3, 430X30X3, 450X30X3, 500X30X3, 510X30X3, 600X30X3, 610X30X3, 630X30X3, 640X30X3 |

| Sales Unit |

Be the first to review “Woodworking W4% Planer Blade” Cancel reply

You must be logged in to post a review.

This site uses Akismet to reduce spam. Learn how your comment data is processed.

Related products

Jointing & Planing

Jointing & Planing

HSS W18% Planer Blade

Jointing & Planing

4 Teeth Woodworking Machinery Finger Joint Combination Cutter for spindle machine

Jointing & Planing

4 Teeth Woodworking Machinery Finger Joint Bottom Cutter for Spindle Shaper

HSS W18% Planer Blade

W18 High Speed Steel Planer Knife Blades for Planer Tool Wood Line Machine 400mm 410mm x 25mm x 3mm

Jointing & Planing

Reviews

There are no reviews yet.