Woodworking Accessories Tips

Milling vs Drilling: Key Differences and Applications in Manufacturing

Drilling Explained

Drilling is the process of creating cylindrical holes in a workpiece using a rotating cutting tool called a drill bit. The main purpose of drilling is to produce holes with precise dimensions and depths. This process is commonly used in manufacturing to create holes for fasteners like screws, bolts, and rivets, or to accommodate parts such as shafts, pins, and dowels.

Milling Process

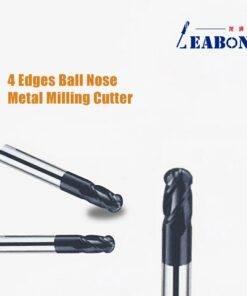

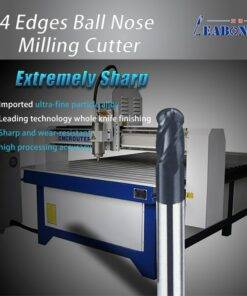

Milling, on the other hand, is a versatile machining operation that removes material from a workpiece using a rotating multi-point cutting tool called a milling cutter. Unlike drilling, milling can create a variety of shapes, including flat surfaces, slots, gears, threads, and complex contours. It’s a highly adaptable process used across industries for manufacturing components with intricate designs.

Differences Between Drilling and Milling

Drilling and milling are two distinct machining processes, with key differences in motion, tools, cutting mechanisms, and applications.

Motion and Mechanism

The primary difference lies in the motion involved. Drilling uses a linear motion of the drill bit along the workpiece’s axis, creating a straight hole. In contrast, milling combines both rotational and linear movements of the milling cutter, allowing for cutting along multiple axes and producing more complex shapes.