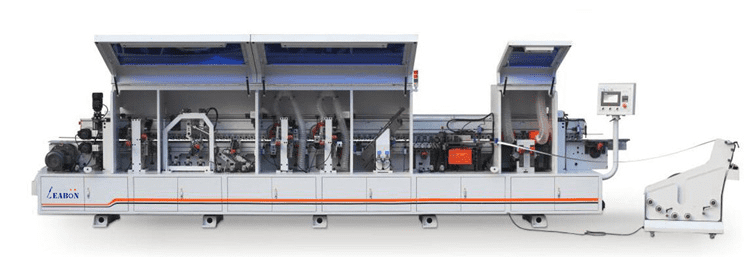

Woodworking Machine Tips

Common faults of edge banding machines and their solutions

1. Startup problem

1. The edge banding machine cannot start.

Solution: Check whether the power plug is plugged in securely, check whether the power switch is turned on, and check whether the power cord is damaged and needs to be replaced.

2. After the edge banding machine is started, there is a flickering or no response phenomenon.

Solution: Check if the control board is in poor contact or damaged, check if the power supply is sufficient, and whether the control board needs to be replaced.

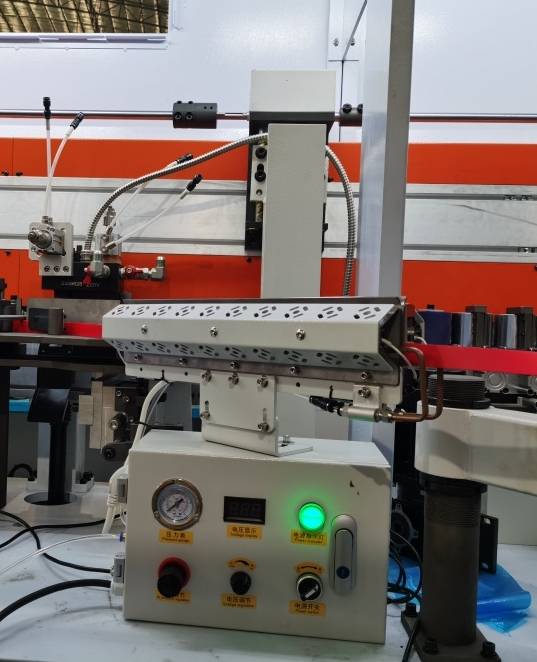

2. Heating problem

1. The edge banding machine is not heated enough.

Solution: Check whether the heating device is working properly, check whether the power supply of the heater is normal, check whether the power cord is damaged. If all of the above are normal, the heater needs to be replaced.

2. The edge banding machine is overheated.

Solution: Check whether the heater is aging and needs to be replaced, check whether the temperature controller is normal, and check whether the heater has poor contact or is damaged.

3. Feeding problem

1. The edge banding machine stops feeding.

Solution: Check whether the drive system is working properly, check whether the motor is working properly, check whether the guide rail or pulley is stuck or foreign objects enter, and clean or replace the damaged parts.

2. The edge banding machine feeds abnormally.

Solution: Check whether the feeding device is damaged, check whether the control system of the equipment is normal, check whether the power cord of the feeding device is normal, and whether there is a power or line failure.

4. Cutting Problems

1. The edge banding machine does not cut completely.

Solution: Check whether the tool is blunt or damaged, check whether the cutting motor is working properly, check whether the cutting pressure is sufficient, and adjust the cutting parameters or replace the tool.

2. The edge banding machine does not cut accurately.

Solution: Check whether the cutting system is tight, check whether the cutting motor and pressure wheel are working properly, and check whether the tool is installed correctly or needs to be replaced.

The above are common faults and solutions for edge banding machines. If you encounter other problems during use, you need to check and solve them in time according to the on-site situation. Please make sure to turn off the power to the edge banding machine before repairing the equipment and take necessary safety measures.