Looking for the right drill bit for boring applications? Whether you’re using a CNC, drill press, or a dedicated boring machine, choosing the correct bit is critical for accuracy, durability, and performance. In this guide, we’ll explore the different types of boring drill bits, what makes each unique, and how to choose the best one for your material and machine.

Category Archives: Woodworking Accessories Tips

Tips for select and use of woodworking accessories and tools.

🔧 Conheça a fresa ideal para cortes em plástico e acrílico

Se você trabalha com CNC e busca acabamentos impecáveis em materiais como acrílico, PVC ou ABS, a resposta está na fresa de metal duro com um só gume da Foshan Leabon Machinery Company Limited.

Introduction

CNC woodturning tools are essential for modern woodworking, providing precision, efficiency, and durability. These tools are used to shape wood by rotating a workpiece against a cutting tool, allowing for intricate designs and high-quality finishes.

Selecting the right CNC wood lathe cutter is crucial for achieving the best results in woodworking. In this article, we will explore five common types of CNC woodturning tools, their advantages, and their best applications.

1. Surface Heat Treatment – Purpose: To alter the metallurgical structure of the tool surface, increasing surface hardness and thereby enhancing wear resistance. – Methods: Include quenching, tempering, carburizing, nitriding, and other heat treatment processes. These methods can form high-hardness martensite or other strengthened phases on the tool surface, improving its resistance to mechanical abrasion. […]

Polycrystalline Diamond (PCD) tooling is an advanced cutting technology, widely used in industries such as woodworking, composites, and manufacturing. Known for its exceptional hardness, abrasion resistance, and long-lasting performance, PCD tooling has been transforming the way businesses approach machining. In this article, we’ll dive into what PCD tooling is, its benefits, applications, and why it’s become a preferred choice for industries seeking precision and durability in cutting tools.

In the world of machining, drilling and milling are two fundamental processes that serve distinct roles in shaping materials. While both are designed to remove material from a workpiece, they differ significantly in their techniques, tools, applications, and outcomes. Understanding these differences is crucial for selecting the appropriate method for any given manufacturing project. This article will delve deeper into the two processes, providing a detailed comparison of their functions, tools, applications, and the machines used for each.

Turning metal and plastic parts is a core part of manufacturing, with material selection being critical to the performance and durability of the final product. Turning involves rotating a workpiece, usually a cylinder, and shaping it with a cutting tool. The material chosen impacts everything from the machining process to the end-use characteristics. Below, we’ll explore four popular materials used in turning: aluminum, brass, stainless steel, and plastics.

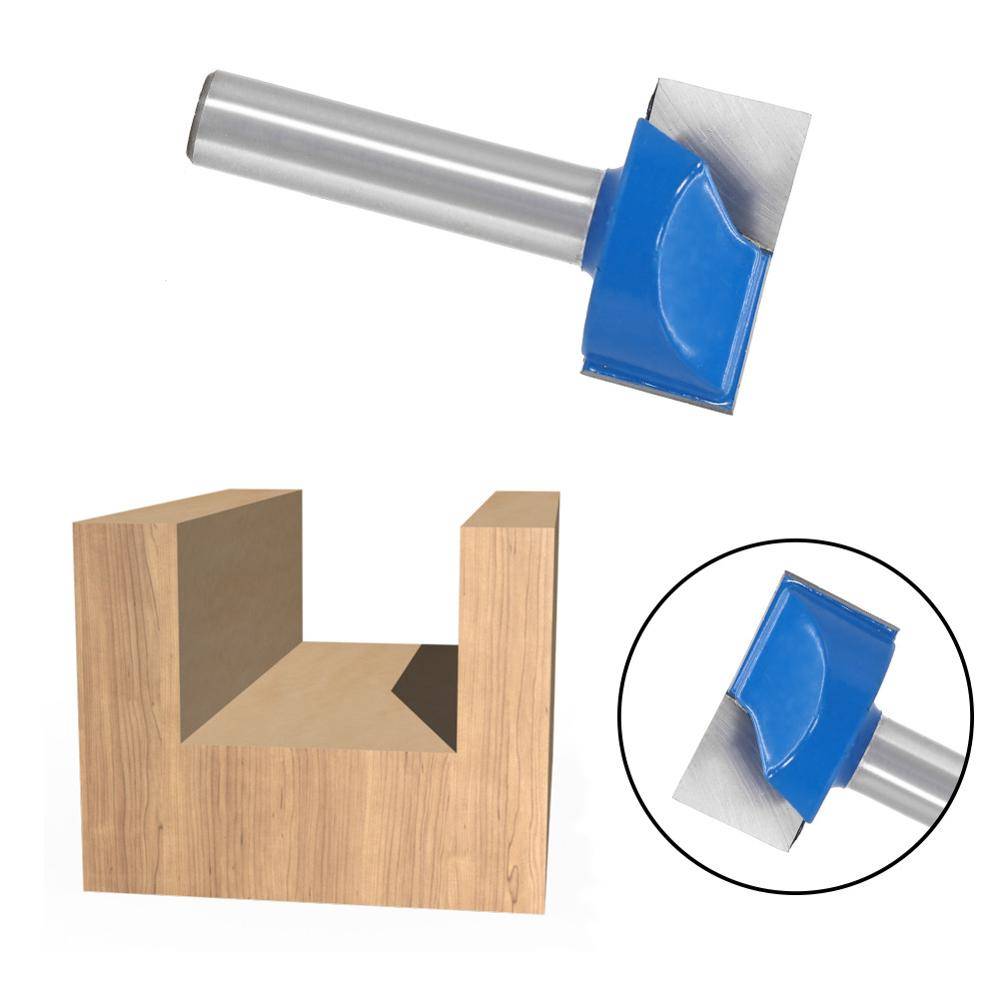

Plunge routing is a woodworking technique where the bit cuts vertically down into the material rather than from the side or edge. This method is essential for creating clean, precise holes, slots, or patterns, but it requires the right type of bit to ensure safety and quality.

CNC milling machines are the backbone of modern manufacturing. They are used to cut and shape materials like metal, wood, and plastic with high precision. Whether you’re working with a vertical or horizontal CNC mill, understanding the key parts of a CNC mill is crucial to making sure the machine performs well and produces quality parts. At Leabon, we specialize in CNC milling solutions that guarantee exceptional results for your manufacturing needs. If you want to know more about our services, contact us at export@carpentryaccessories.com.