Woodworking Accessories Tips

Tungsten vs. Tungsten Carbide: Key Differences Explained

1. What Are Tungsten and Tungsten Carbide?

Tungsten and tungsten carbide share a chemical connection, but they have distinct properties that make them suited for different uses.

Tungsten is a chemical element (symbol W) known for its high melting point and strength. It is a dense, grayish-white metal that is mainly used in alloys. Tungsten itself is not often used in its pure form, except in specific applications where heat resistance or high density are needed.

Tungsten carbide is a compound made by combining tungsten with carbon (chemical formula WC). It is much harder and more wear-resistant than tungsten, making it ideal for heavy-duty industrial uses.

2. How Do Tungsten and Tungsten Carbide Differ in Hardness?

Hardness is a key factor in selecting materials for industrial applications, and this is where tungsten and tungsten carbide differ significantly.

Tungsten has a hardness rating of 7.5 to 8 on the Mohs scale. It’s tough and can resist heat well, but it is not as hard as tungsten carbide.

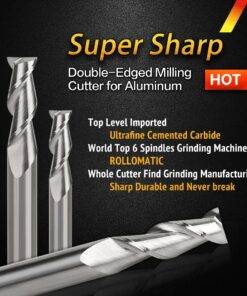

Tungsten carbide, with a hardness rating of 9 to 9.5, is one of the hardest materials on Earth. Only diamonds are harder. This extreme hardness makes tungsten carbide ideal for cutting tools, mining equipment, and other tools that experience heavy wear.

3. Applications: Where Each Material Excels

Tungsten and tungsten carbide are used in different industries, each taking advantage of the material’s unique properties.

Tungsten Carbide:

Because of its hardness and wear resistance, tungsten carbide is used in industries that require tools to endure extreme conditions. It’s ideal for:

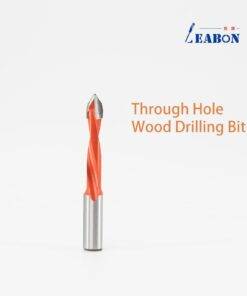

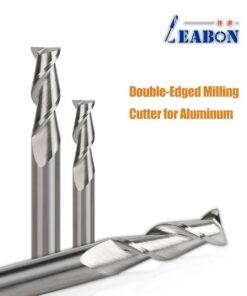

- Cutting Tools: Tungsten carbide is commonly found in drill bits, saw blades, and cutting tools. Its hardness allows these tools to stay sharp much longer, even when cutting through tough materials like metal or concrete.

- Mining & Construction: Tungsten carbide is widely used in mining tools and construction equipment due to its durability. These tools last longer in harsh conditions, even under constant pressure.

- Oil & Gas: Tungsten carbide is also used in valves, bushings, and seals in the oil and gas industry. Its wear resistance helps components last longer in high-pressure, high-temperature environments.

Tungsten:

Tungsten is not as hard as tungsten carbide but has its own strengths in other areas. It is mainly used in applications that require heat resistance, density, and electrical conductivity. Here’s how tungsten is used:

- Alloys: Tungsten is commonly used in high-speed steel and other alloys for cutting tools and machinery that need to withstand high temperatures.

- Electrical & Thermal Applications: Tungsten conducts electricity and heat extremely well. It is used in electrical contacts, light bulb filaments, and heating elements.

- Aerospace & Defense: Tungsten’s high melting point makes it perfect for aerospace applications, including rocket nozzles and missile components, where materials face extreme heat and pressure.

4. Physical Properties: Comparing Density, Conductivity, and Melting Points

Tungsten and tungsten carbide also differ in other physical properties, such as density, thermal conductivity, and melting points.

Tungsten:

- Density: Tungsten has a very high density (around 19.3 g/cm³), making it useful in applications like radiation shielding and counterweights.

- Conductivity: Tungsten is an excellent conductor of heat and electricity.

- Melting Point: Tungsten has the highest melting point of any metal, about 3422°C (6192°F). This makes it ideal for high-temperature applications, such as in aerospace components.

Tungsten Carbide:

- Density: Tungsten carbide is slightly less dense than tungsten (around 15.6 g/cm³), but still very heavy compared to most other materials.

- Thermal Expansion: Tungsten carbide has a low coefficient of thermal expansion, meaning it doesn’t expand or contract much with temperature changes.

- Melting Point: Tungsten carbide has a high melting point of around 2870°C (5198°F), which is lower than tungsten’s but still much higher than most materials.

5. Cost: Tungsten vs. Tungsten Carbide

Another key difference between these materials is cost.

Tungsten is generally less expensive than tungsten carbide. It’s easier to process, and its applications require less advanced manufacturing techniques.

Tungsten Carbide, being a more complex material, requires additional processing and manufacturing steps, which makes it more expensive. However, the higher cost is often justified by its superior performance in demanding applications.

6. Conclusion: Choosing the Right Material for Your Needs

Both tungsten and tungsten carbide are valuable materials, but they are suited to different applications due to their distinct properties. Tungsten is the material of choice when you need high density, heat resistance, or electrical conductivity. It’s commonly used in electrical components, alloys, and aerospace parts.

On the other hand, tungsten carbide is best for applications requiring hardness and wear resistance. It excels in cutting tools, mining, and construction equipment, where tools are subjected to extreme wear.

By understanding the differences between these two materials, you can select the one that best meets your needs and ensure better performance and longer-lasting tools