Woodworking Accessories Tips

How to achieve high-quality edge banding when creating a minimalist style handle-free cabinet door panel?

In the field of minimalist home design, the handle-free design has long become a widely recognized trend, and it indicates the development direction of future home design, and is favored and sought after by consumers. The reason why this design is highly praised is mainly due to its neat and generous lines, which makes the overall facade present an extreme sense of simplicity and fashion. At the same time, abandoning the traditional raised handles not only improves the appearance of the home, but also effectively avoids the risk of bumps, making people more worry-free and labor-saving when choosing home furnishings, and cleaning and maintenance are also more convenient.

In addition, traditional panel furniture often uses right-angle edge banding, which results in monotonous horizontal and vertical lines on the appearance of household items, which not only lacks aesthetics, but also has serious homogeneity. The handle-free design, while removing the handle, cleverly uses a variety of innovative design elements such as J-shaped, L-shaped, and 45-degree oblique straight edges, which not only improves the convenience of use, but also maintains the harmony and unity of the home. This design gives household items a sense of agility, simplicity without losing elegance, and reveals quality and style in a low-key manner, truly realizing the perfect fusion of form and function.

01 What is edge banding technology

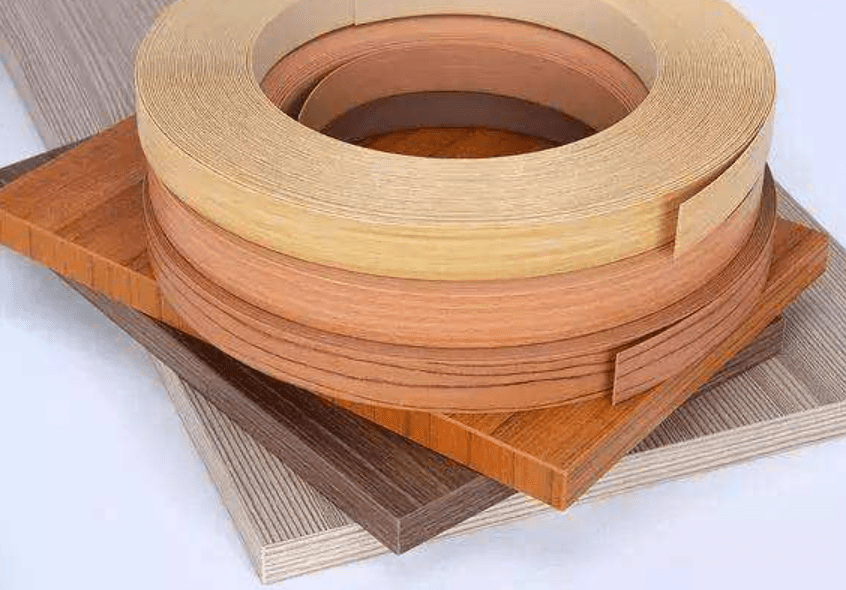

Edge banding is a common processing method for processing the edge of a board. It uses strip edge banding materials such as wood strips, veneers, thin board strips, veneer strips, melamine resin decorative board strips, PVC strips, ABS strips, etc., which are coated with glue and pressed on the edge of the board to seal the periphery of the board. Edge banding can be divided into manual edge banding and mechanical edge banding.

02 Soft-formed edge banding for special-shaped panels

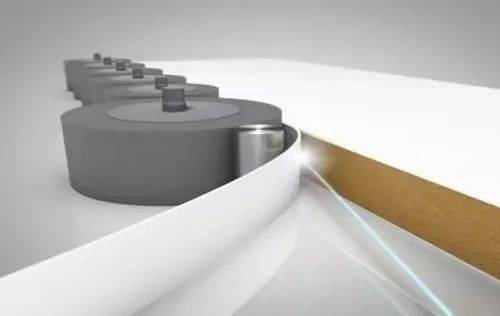

Soft-formed edge banding is also called special-shaped edge banding. It is mainly used to process panels with formed edges or special-shaped edges. For example, J-shaped, L-shaped, 45-degree straight edge, duckbill-shaped and other conventional handle-free edge banding can all be achieved with soft-formed edge banding machines. The emergence of soft-formed edge banding machines meets the diverse needs of furniture formed edges.

The realization of soft-formed edge banding technology ultimately depends on high-performance equipment. Traditional special-shaped edge banding has a simple appearance, poor effect, high production cost, and relatively slow speed. The emergence of today’s soft-formed edge banding machines not only meets the aesthetic needs of consumers, but also greatly enhances the core competitiveness of enterprises.

Soft forming edge banding machines can solve the problem of edge banding of special-shaped edges such as straight edges, oblique straight edges, duckbill shapes, L-shaped shapes, etc. It is equipped with a formed pre-milling unit, which can cut the formed surface at high speed. The tool replacement is also relatively convenient. Several common handle-free designs can be covered. Usually one machine can meet a variety of edge banding needs, which can greatly reduce the investment in equipment, site and labor, and improve the quality and efficiency of processing.

03 Conclusion

To create a minimalist handle-free cabinet door panel, high-quality edge banding technology is essential. By selecting appropriate edge banding materials, using advanced edge banding technology, and adopting intelligent and automated production equipment, we can not only achieve simplicity and fashion in home design, but also provide consumers with a better and more comfortable use experience.