Woodworking Accessories Tips

Choosing the Right Bit for Plunge Routing: A Detailed Guide

1. Understanding Plunge Routing

Plunge routing involves inserting the router bit into the material without pre-drilling. The technique is often used for decorative inlays, joinery, and sign-making. It demands a bit capable of cutting directly into the surface while maintaining smooth operation.

2. Types of Bits Suitable for Plunge Routing

Spiral Bits

Spiral bits, particularly up-cut designs, are ideal due to their efficiency in removing debris and producing clean cuts. These bits also minimize overheating and help maintain precision.

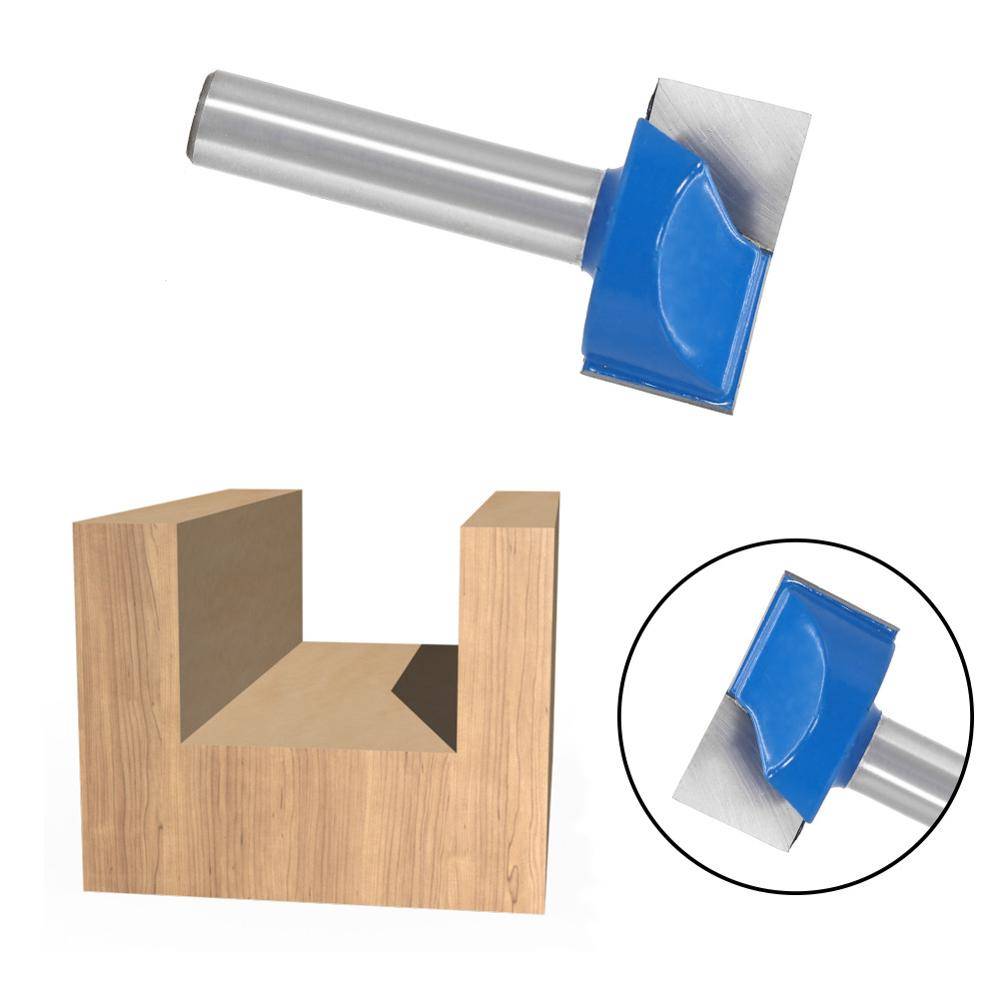

Straight Bits

Straight bits can work for plunge routing, but they must feature a cutting edge across the bottom to penetrate the material effectively.

Leabon offers a wide range of router bits, including the standard straight bits and spiral router bits mentioned above. It is a one-stop shop for CNC tool accessories, CNC spare parts, woodworking tools, and more.

3. Key Features to Look for in a Bit

Sharp Bottom Cutting Edges

Bits with sharp cutting edges on the bottom are essential for smooth entry into the material.

Helical (Spiral) Grooves

These grooves aid in lifting debris out of the cut, keeping the working area clean and reducing friction.

Durable Material Composition

Opt for high-speed steel (HSS) or carbide-tipped bits. Carbide is especially durable, lasting longer and performing well under heavy use.

Secure Mounting

The bit must fit securely in the router to prevent wobbling or detachment during operation.

4. Material and Maintenance Tips

Material: Use bits specifically designed for the material being worked on, whether it’s wood, plastic, or composite.

Cooling and Maintenance: Avoid overheating by controlling the cutting speed. Regularly clean and sharpen bits to extend their lifespan.