Woodworking Accessories Tips

The Essential Parts of a CNC Mill and How They Work

1. What Is a CNC Mill and How Does It Work?

A CNC mill is a computer-controlled machine that uses a rotating cutting tool to remove material from a workpiece. Unlike a lathe, which spins the workpiece while the tool moves into it, a CNC mill keeps the workpiece stationary while the cutting tool moves around it.

The process starts by clamping the material onto the worktable. After that, the machine follows instructions from a CAD or CAM model. These instructions are converted into G-code, which tells the machine exactly how to move the cutting tool to shape the material.

CNC milling machines are known for their precision and ability to create both simple and complex parts, including flat, curved, concave, and convex surfaces. Leabon offers high-quality CNC milling services, using the latest technology to ensure that your parts meet the highest standards. Whether you need one-off custom parts or mass production, we have the tools and expertise to meet your needs.

2. Key Parts of a CNC Mill and Their Functions

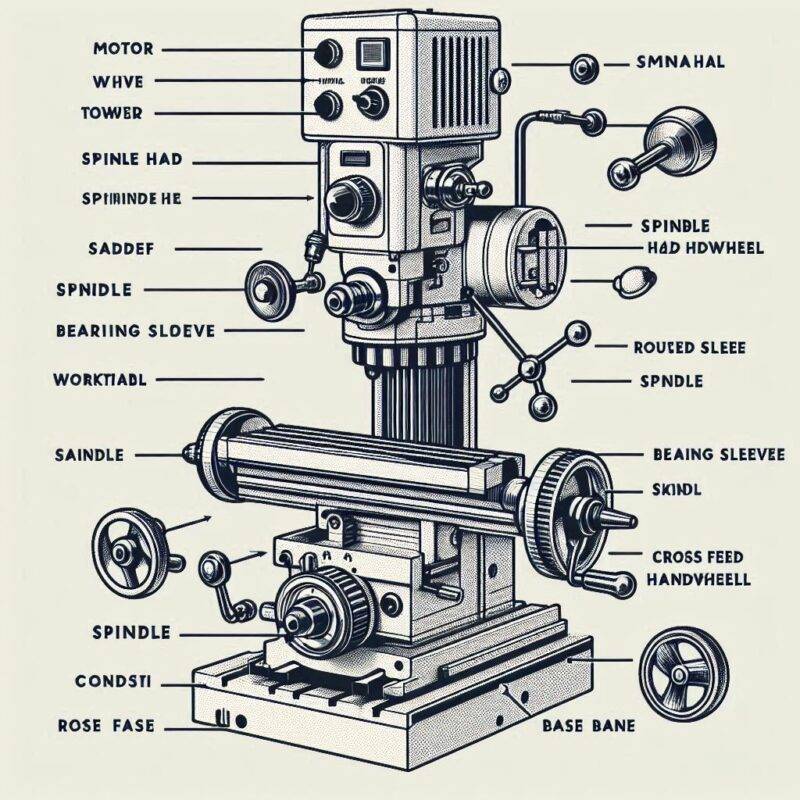

A CNC milling machine has several key parts. Each part plays an important role in the milling process. Here’s an overview of the essential parts of a CNC mill and how they contribute to its operation:

Column and Base

The column and base are the foundation of any CNC milling machine.

- Column: The column, made from cast iron, supports other key parts, like the knee and worktable. It also contains the oil and coolant system, which helps keep the machine operating smoothly.

- Base: The base holds the machine’s weight. It helps reduce vibrations during machining, which is crucial for maintaining precision, especially when making deep or heavy cuts.

At Leabon, we use top-quality materials to build stable, vibration-resistant CNC mills. This approach ensures high-precision results with every job.

Knee

The knee is attached to the column and provides vertical movement to the worktable.

- Vertical Adjustment: The knee moves up and down using an elevating screw. This allows the operator to control the depth of the cut.

- Support for Saddle: The knee also supports the saddle, which moves the workpiece horizontally (left and right). This adjustment is important for positioning the workpiece accurately for different cuts.

Our CNC milling machines at Leabon are equipped with high-precision knee and saddle systems to ensure accurate vertical and horizontal adjustments. This setup makes it easier to machine complex parts.

Power Feed Mechanism

The power feed mechanism controls the movement of the workpiece in three directions:

- Longitudinal (X-axis): It moves the workpiece left and right.

- Transverse (Y-axis): It moves the workpiece in and out.

- Vertical (Z-axis): It moves the workpiece up and down.

This mechanism allows for smooth, consistent motion of the workpiece during machining, which ensures accurate cuts. You can adjust the feed rate using the CNC machine’s controls or manually by adjusting the speed.

At Leabon, we use state-of-the-art power feed systems in our CNC mills, providing maximum control and efficiency for your projects.

Work Table

The work table is where the actual machining takes place.

- Clamping the Workpiece: The workpiece is clamped to the table using vises, clamps, or other holding devices. This setup ensures the workpiece stays in place while the cutting tool moves around it.

- Movement of the Table: The table moves along the X and Y axes. This movement helps position the workpiece for each cut. The lead screw system controls the movement, ensuring that the table moves smoothly.

The work table is central to the machining process because it holds the material securely and moves it into the correct position for cutting. At Leabon, we offer precision work tables designed to handle various workpieces, ensuring top-notch machining performance.

Spindle

The spindle is one of the most important parts of a CNC mill. It holds and rotates the cutting tools that do the actual cutting.

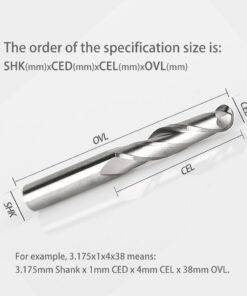

- Tool Holding: The spindle can hold various types of cutting tools, such as end mills, face mills, and drill chucks. The spindle rotates these tools at high speeds to cut through materials like metal, wood, and plastic.

- Types of Milling: The spindle allows the CNC mill to perform a wide range of milling tasks, including:

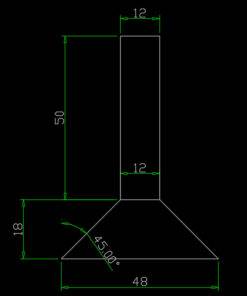

- Plane Milling: Cutting flat surfaces.

- Surface Milling: Smoothing flat surfaces.

- Angular Milling: Cutting at specific angles.

- Groove Milling: Cutting grooves or slots.

- Gear Milling: Cutting gears.

- Cam Milling: Shaping cam profiles.

The spindle’s rotation is crucial for enabling the CNC mill to perform different types of milling jobs. This feature makes it one of the most essential parts of a CNC mill. At Leabon, we ensure our spindles are of the highest quality, which gives you precision in every cut.

3. How CNC Mills Are Used in Manufacturing

CNC mills are incredibly versatile and can be used in a variety of industries:

- Metalworking: CNC mills are often used to machine metals like aluminum, steel, and stainless steel. This is especially important in industries like aerospace and automotive, where precision is crucial.

- Precision Parts: CNC mills are perfect for creating parts with tight tolerances and complex shapes. This capability makes them essential in industries that require high-precision components, such as medical devices and industrial machinery.

- Complex Geometries: With their ability to create parts with detailed features, CNC mills are ideal for manufacturing intricate and complex components. Traditional methods would find it difficult to produce these components.

At Leabon, we use CNC mills to create high-precision parts for various industries. Our aim is to ensure that every product meets your exact specifications. If you need expert CNC milling services, contact us at export@carpentryaccessories.com.

4. Conclusion

CNC mills are powerful and precise machines that are essential for modern manufacturing. The key parts of a CNC mill—like the column, base, knee, power feed mechanism, worktable, and spindle—work together to create high-quality parts with great accuracy.

By understanding the functions of each of these parts, manufacturers can ensure their CNC milling machines operate at their best. Whether you’re machining simple components or complex parts with tight tolerances, the parts of a CNC mill play a critical role in achieving precise, high-quality results every time.

For all your CNC milling needs, Leabon is your trusted partner. We provide cutting-edge CNC milling services to ensure your manufacturing processes run smoothly and efficiently. Get in touch with us today at export@carpentryaccessories.com to discuss how we can assist you with your next project.