125mm 160mm Industrial Grade Wood Round Saw Blade Carpentry Tool with Tungsten Carbide Tipped Material for Table Saw Machine

$40.10 – $65.63

What’s Industrial Grade Saw Blade

Woodworking circular saw blades have different grades including DIY, General and Industrial Grades, etc. The main differences are from following aspects:

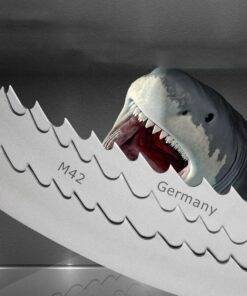

Different Saw Body and TCT Material, Durability (Life Span)

Whether the thickness of the saw body is uniform

Whether the outer circle and the inner circle are concentric

Processes of sawtooth welding.

For Industrial Grade Saw Blade, its life can lasts at least 10-30 times as General and DIY grade blades, the saw body is uniform to keep the work piece cutting precision, the outer circle and the inner circle are concentric to insure no cutting tolerance for different work piece cutting deepth, the sawtooth are also fine welded to insure no stop for industrial mass quantity and long time continually cutting work.

Industrial Grade blade can be used to replace DIY and General Grade, but DIY and General Grade blades are not good for Industrial work even it’s coated with Nano or other coating. Because of the big difference on production cost, Industrial Grade Saw Blade price is much higher than DIY and General Grade.

All Leabon shop Circular Saw Blades are Industrial Grade.Plz be carefully to choose appropriate grade saw blade against your working requirement.Also feel free to contact us for any order more than 5 pcs before you buy, because of the heavy weight, we will customize you the best solution either Fastest Delivery or Most Saving way against your destination and quantity.

Specification

| Product Name | Woodworking Circular Saw Blade | ||

| Brand Name | LEABON | ||

| Type | Sliding Table Saw Blade | ||

| Color | Sliver | ||

| Material | TCT / STEEL | ||

| Dimension/mm(Dia*Teeth thickness-Body Thickness*Bore*Teeth): | |||

| 125×3.3-4.3/2.5x22x24T | 160×3.0-4.0/2.2×25.4x36T; | ||

| Package | 1pc in each package |

Features

Applicable Equipment and Processing Material

100% brand new Woodworking Circular Saw Blade is applicable for sliding table and reciprocating saw with high quality,and to process various woods,like MDF, solid wood and shaving board, while the cut surface of the wood board processed by our saw blade is smooth and does not collapse.

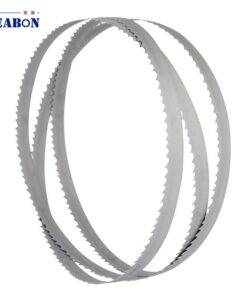

Product Real Shot

| Weight | 0.8 kg |

|---|---|

| Color | 125×3.3-4.3x22x24T, 160×3.0-4.0×25.4x36T |

| Origin | CN(Origin) |

| Size | 125/160×3.3/4.3×22/25.4×24/36T |

| Model Number | LBSB20 |

| is_customized | Yes |

| Finishing | White |

| Number of Pcs | 1 Pc |

| Blade Type | Circular Saw Blades |

| Blade Material | Alloy Steel |

| Usage | Commercial Manufacture |

| Products Grade | Woodworking Industrial Grade |

Be the first to review “125mm 160mm Industrial Grade Wood Round Saw Blade Carpentry Tool with Tungsten Carbide Tipped Material for Table Saw Machine” Cancel reply

You must be logged in to post a review.

This site uses Akismet to reduce spam. Learn how your comment data is processed.

Related products

Edge Banding Machine Accessories

Reviews

There are no reviews yet.