Woodworking Accessories Tips

What buyers need to know before customizing drill bits

What buyers need to know before customizing drill bits

The advantages of customized drill bits

Improving Drilling Efficiency

Customized drill bits can be customized based on factors such as your drilling purpose, material, size, shape, color, etc., to match your drilling needs and conditions, improve drilling speed and quality. For example, if you need to drill holes on hard materials, you can choose to use drill bits made of high-strength materials such as hard alloy or diamond to increase wear resistance and cutting force; If you need to drill holes on irregular or curved surfaces, you can choose to use special shapes such as curved or conical drills to adapt to the curvature and angle of the surface; If you need to drill in dark or low light environments, you can choose to use eye-catching colors such as bright or fluorescent drill bits to improve visibility and safety.

Improving Drilling Accuracy:

Customized drill bits can be customized according to your drilling accuracy requirements, thereby reducing errors and deviations, improving drilling accuracy and consistency. For example, if you need to drill holes on small or precise components, you can choose to use micro or ultra-fine drill bits to increase accuracy and flexibility; If you need to drill holes on multiple layers or composite materials, you can choose to use complex structures such as multi blade or composite drills to increase stability and adaptability; If you need to drill at specific or standard locations, you can choose to use drill bits with auxiliary functions such as scales or markings to increase accuracy and convenience.

The process of customizing drill bits

Consultation:

This is the first and most important step in customizing drill bits. In this step, you need to contact the supplier of the customized drill bit and tell them what kind of drill bit you want to customize, including your drilling purpose, material, size, and shape. The supplier will provide you with some feasible solutions and quotations based on your needs and conditions for you to choose and compare. You can also raise your questions and questions with the supplier and ask them to provide you with answers and suggestions.

Design

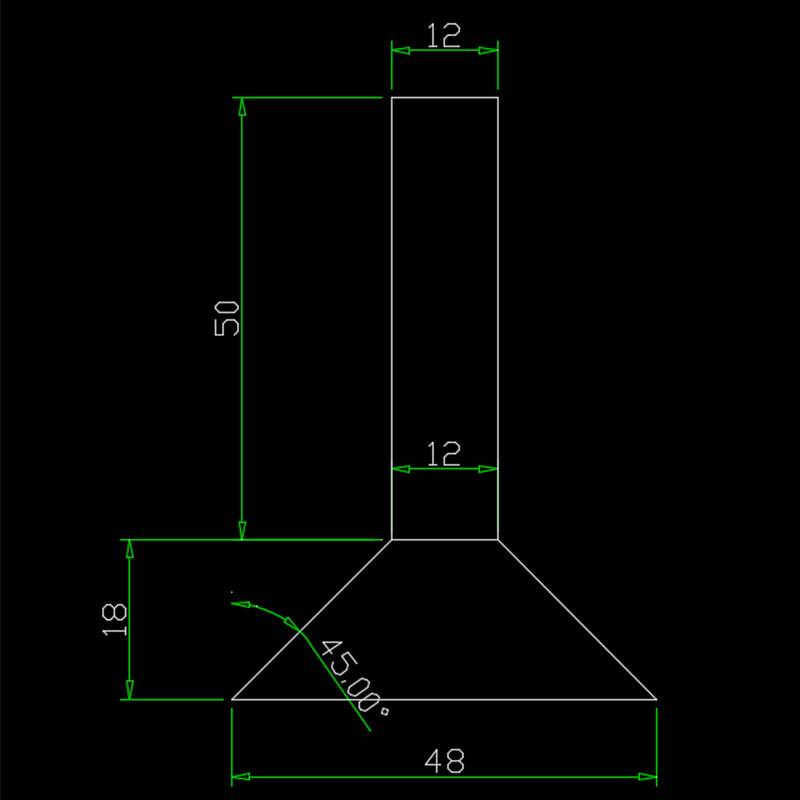

This is the second and most interesting step in customizing drill bits. In this step, you can choose your preferred drill bit type, material, size, shape, color, etc. based on the solution provided by the supplier, or provide your own ideas and suggestions, and have the supplier design a unique drill bit for you. The supplier will produce a detailed design drawing based on your selection and requirements, and provide you with a sample to see and feel the appearance and performance of your customized drill bit.

Confirmation:

This is the third and most critical step in customizing drill bits. In this step, you need to carefully review and provide feedback after receiving the design drawings. If there are any dissatisfaction or modifications that need to be made, you can communicate with the supplier in a timely manner and make adjustments until you are completely satisfied. In this step, you also need to sign a contract with the supplier and pay a certain proportion of the deposit to ensure the rights and responsibilities of both parties.

Production:

This is the fourth and most time-consuming step in customizing drill bits. In this step, the supplier will start producing your customized drill bits based on the design drawings you have confirmed, and complete and ship them within the specified time. In this step, you can keep in touch with the supplier and keep track of the production progress and status of your customized drill bit at any time.

Receipt

This is the fifth and most exciting step in customizing drill bits. In this step, you will receive your customized drill bit and can double check and use it. If there are any problems or dissatisfaction, you can contact the supplier and seek solutions. In this step, give the supplier an evaluation and feedback.